Klüber Lubrication is a specialist for lubrication. We provide lubrication solutions for all extreme conditions, including conveyor belts. With our new conveyor lubricant, we have combined a lubricant with a cleaning agent to deliver an unmatched value proposition that protects you from a vicious circle of lubricating, cleaning and wear on conveyor belts.

Would you like to know more about this value proposition? Then you have come to the right website…

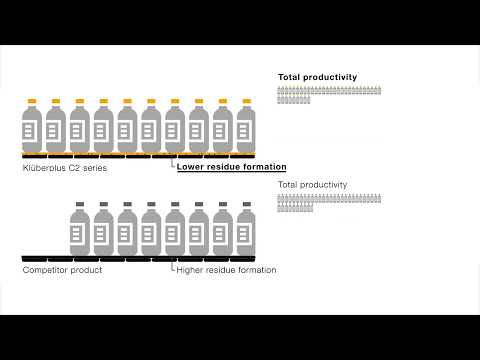

Klüber Lubrication regards the issue of productivity and hygiene on conveyor belts in the food industry as an opportunity. Our dry lubricants not only provide better lubrication and cleaner and more hygienic chains; they also offer a reduced cleaning effort, improved process reliability and reduced operating costs when compare to wet lubricants.